Process design is a fundamental aspect of manufacturing, serving as the bridge that connects a concept or idea to the tangible reality of a product. It is a meticulous and critical process that involves a series of well-planned steps, each playing a vital role in the transformation from an initial idea to a final product. In this article, we will explore the general steps involved in process design, emphasizing the importance of precision, attention to detail and qualities exemplified by companies like cxinforging.

Conceptualization

The journey from concept to reality commences with a simple idea or concept. This initial spark can originate from various sources, including market demands, consumer needs, technological innovations, or industry trends. It is the foundational point upon which the entire process design is built. For a clearer illustration, let's consider an example: the manufacturing of a forged component for the automotive industry.

Defining Objectives

Once the concept is firmly established, the next step is to define clear and specific objectives. What are the goals that need to be achieved through this manufacturing process? In our automotive component example, these objectives could encompass improving fuel efficiency, reducing production costs, ensuring compliance with industry standards, and enhancing overall product quality.

Process Selection

With the objectives in place, the process selection phase begins. This is a pivotal decision-making step, as it determines the methods and technologies that will be employed to manufacture the desired product. Choices may include various manufacturing processes, such as forging, casting, machining, or additive manufacturing, depending on the specific requirements. Each process has its own set of advantages and limitations, and selecting the most suitable one is crucial.

Design and Engineering

Following process selection, the design and engineering phase commences. During this stage, detailed blueprints, CAD models, and simulations are developed to ensure that the product's design is not only functional but also optimized for manufacturing. This step requires thorough consideration of factors such as material selection, structural integrity, and dimensional accuracy.

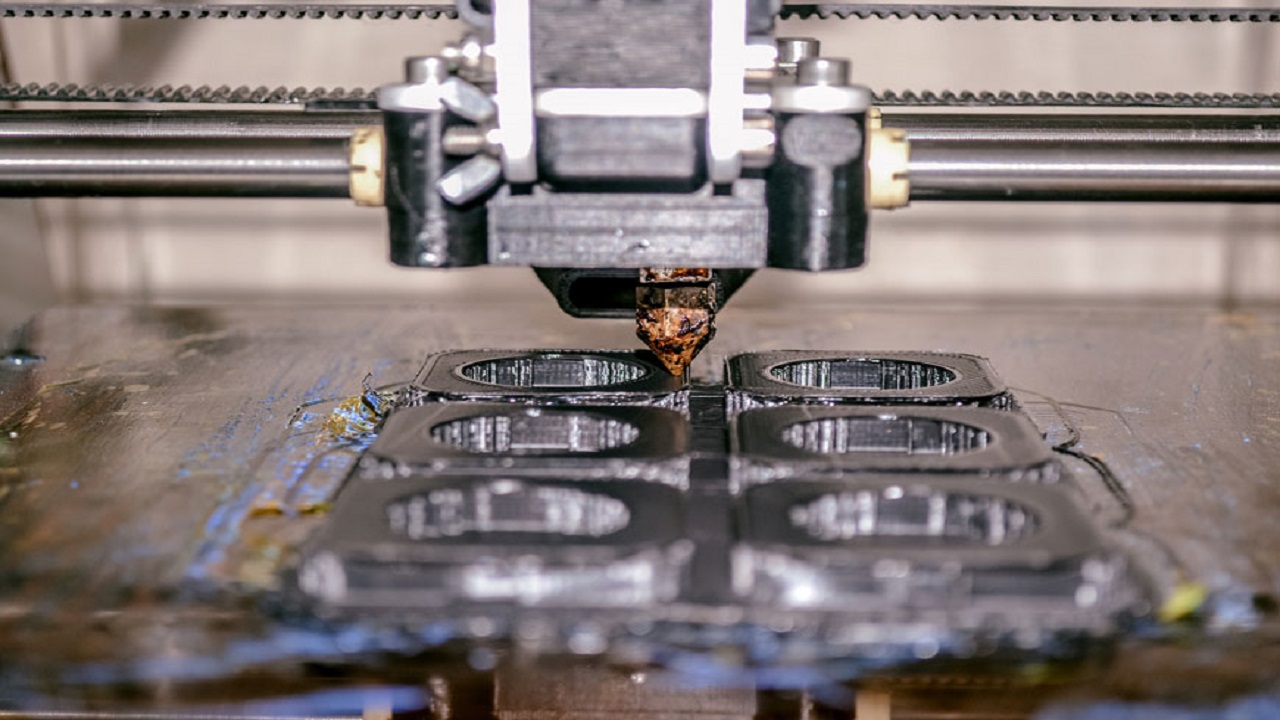

Prototype Development

Before moving on to full-scale production, it is customary to create a prototype. Prototypes serve as tangible representations of the design and allow for practical testing and validation. In our automotive component example, a prototype would be manufactured and subjected to various tests to assess factors like strength, durability, and compatibility with other vehicle components.

Material Selection

Selecting the appropriate materials is a critical aspect of process design. Manufacturers must choose materials that align with their objectives, taking into account factors such as strength, weight, durability, and cost-effectiveness. This step ensures that the final product meets the desired specifications and performance criteria.

Tooling and Equipment

With the design and materials determined, the next phase involves tooling and equipment. Specialized tools, molds, and machinery are manufactured or acquired to facilitate the chosen manufacturing process. This step often necessitates precision machining to ensure that the tools and equipment meet the required specifications.

Quality Control and Testing

Quality control and testing are integral throughout the manufacturing journey. Rigorous quality checks and testing procedures are implemented at various stages to ensure that the product consistently meets the established standards for quality, performance, and safety.

Production and Scaling

Once all preparations are complete, full-scale production can begin. Scaling up from the prototype phase to mass production is a significant milestone. Manufacturers must optimize their processes for efficiency, consistency, and cost-effectiveness while maintaining the high-quality standards established earlier in the process.

Conclusion

Process design is an intricate and essential facet of manufacturing that requires careful planning, precision, and meticulous attention to detail. It serves as the conduit that transforms a concept into a tangible product, providing value to consumers and industries alike. From the initial idea to the final product, every step in the process is essential, contributing to the ultimate success of the endeavor.